Search

Search

Source:新声半导体 Author:新声半导体 Time:2024-05-22

Filter is a very important RF(radio frequency) unit in modern communication, each band of radio signal needs a corresponding bandpass filter. With the continuous development of communication technology, the number of frequency bands supported by smartphones is constantly increasing, and the performance requirements for filters are getting higher and higher, the number of filters loaded in mobile phones is also increasing.

FBAR (Film Bulk Acoustic Resonator), as a new filter technology platform, has the advantages of high power tolerance, small size, low insertion loss, high out-of-band rejection and can be used in UHF, and has become a hot spot in the field of communication research and large-scale commercial development.

How was it born? What is its charm, value and history? Let's unravel its mystery together.

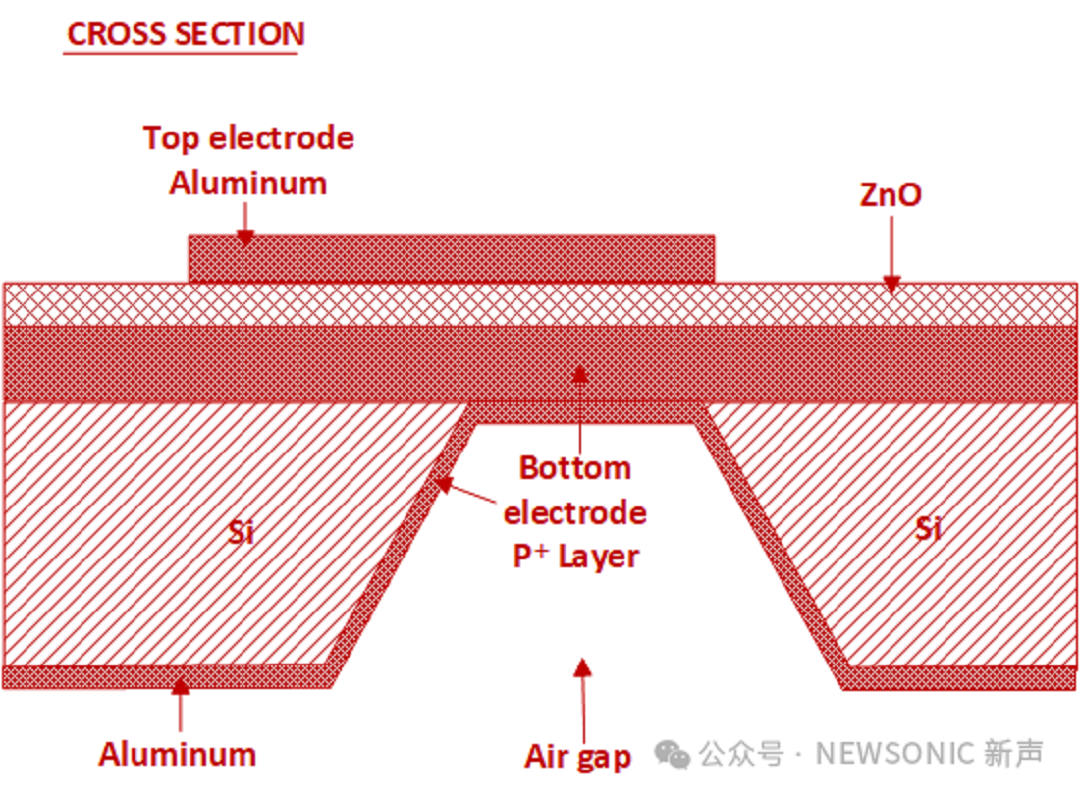

In 1981, Professor Lakin of the University of Southern California and his team published an article titled "Acoustic Bulk Wave Composite Resonators" in the journal Applied Physics Letters, which first proposed a suspended bulk acoustic wave resonators. It is composed of ZnO thin film coated on the Si support structure of thin film. The free surface on both sides of the thin film constitutes the sound reflection boundary and forms a resonator in which the bulk sound wave oscillates. This is the world's first FBAR, the resonant frequency is 435MHz, the parallel resonance Q value is more than 9000, the series resonance Q value is more than 3000, but limited by the material and structure , the effective K2 is only about 0.3%.

At this point, FBAR technology has really attracted wide attention in the industry, and this milestone achievement has laid the foundation for the subsequent development of FBAR.

Figure 1. Schematic diagram of the suspended acoustic resonator published by K. M. Lakin

Image source:Acoustic Bulk Wave Composite Resonators

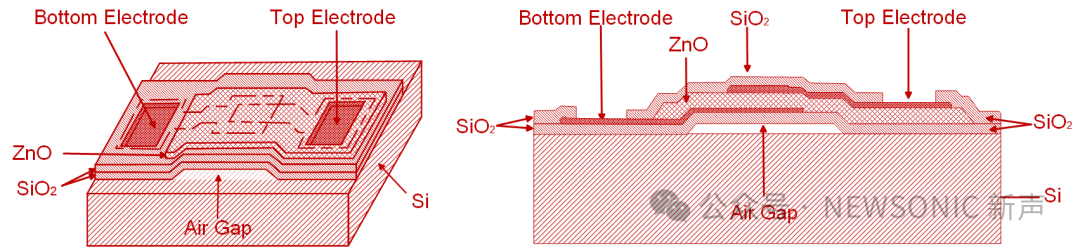

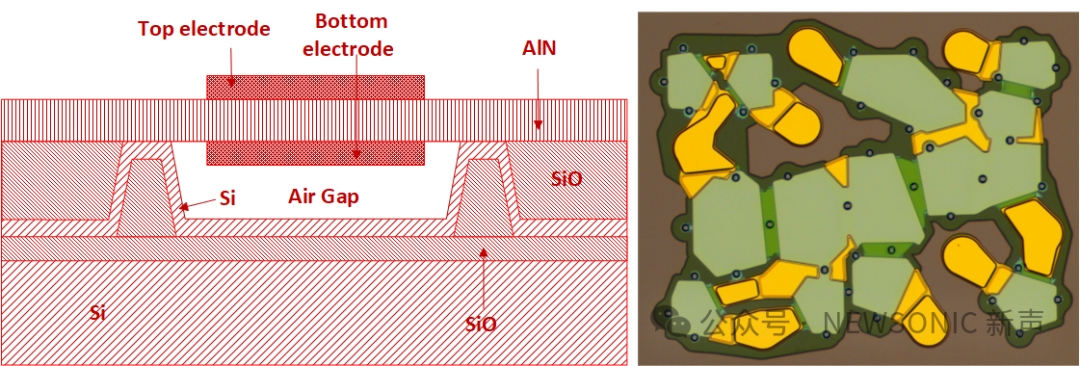

Four years later, researchers H. Satoh, Y. Ebata, H. Suzuki, and C. Narahara from Toshiba's R&D Center in Japan published an article titled "An Air-Gap Type Piezoelectric Composite Thin Film Resonator," in which they mentioned that they were the first to implement FBAR devices based on semiconductor processes. Their structure created a very thin air gap between the silicon substrate surface and the FBAR device to ensure the independence of the resonant cavity. The FBAR used in their experiment still employed ZnO as the piezoelectric layer, a material most commonly used in FBAR research and development during the 1980s.

Figure 2. Schematic diagram of the air-gap type thin film resonator structure.

Source: "An Air-Gap Type Piezoelectric Composite Thin Film Resonator"

In 1990, Krishnaswamy and Rosenbaum expanded the FBAR technology to the GHz frequency band, marking the official entry of FBAR filters into the high-frequency communication field and laying the foundation for their future role as an important driver of the wireless communication technology revolution.

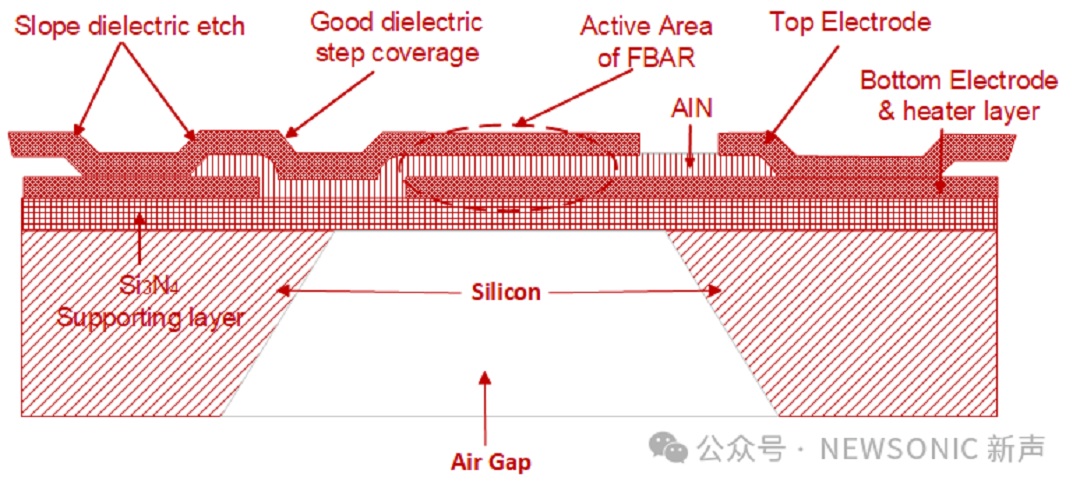

The early 1990s, Dr. Richard Ruby and his team at Hewlett-Packard Labs (Avago) actively engaged in the research and development of radio frequency communication technology. In 1994, he presented "Micromachined Thin Film Bulk Acoustic Resonators" at the IEEE Frequency Control Symposium, where he mentioned that his team had successfully manufactured an FBAR with a Q value of over 1000 and a resonant frequency ranging from 1.5 GHz to 7.5 GHz. The device consisted of a piezoelectric material, aluminum nitride (AlN), sandwiched between two electrodes, with the entire device structure located on a low-stress silicon nitride thin film.

Figure 3. Schematic diagram of the FBAR published by Dr. Richard Ruby

Source:"Micromachined Thin Film Bulk Acoustic Resonators"

Two years later, they proposed the possibility of applying FBAR technology to the telecommunications market (such as mobile phones and other mobile devices) at the IEEE MTT-S International Microwave Conference held in San Francisco and successfully implemented the application of FBAR on mobile phones in the laboratory.

Figure 4. Left: Dr. Richard Ruby and his team. Right: The mobile phone used in the experiment at that time.

Source: "RF Bulk Acoustic Wave Filters for Communications"

Thanks to Dr. Richard Ruby's efforts, FBAR technology gradually matured in Hewlett-Packard Laboratories. In 1999, Agilent Technologies (formerly Hewlett-Packard Laboratories, Avago) successfully developed an FBAR filter for the American PCS1900MHz frequency band and achieved mass production in 2001, while officially proposing the term FBAR.

Public information from the Institute of Electrical and Electronics Engineers (IEEE) shows that Dr. Ruby successfully industrialized FBAR patents from 2001 to 2003 and helped the company mass-produce the first batch of FBAR Duplexers (HPMD7901 and 7904).

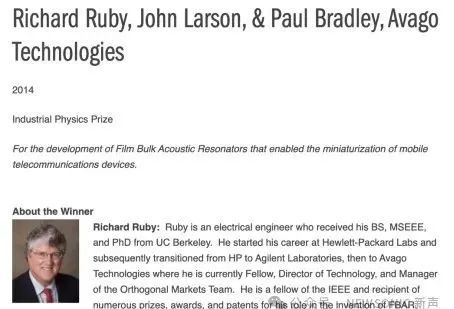

Dr. Ruby was awarded the Industrial Physics Prize by the American Physical Society in 2014 for his outstanding contributions to FBAR technology.

Figure 5. Dr. Richard Ruby receiving the Industrial Physics Prize.

With the commercial success of FBAR technology in 2001, FBAR has rapidly developed in the field of mobile communication. Companies such as Infineon from Germany, Philips from the Netherlands, Motorola, TDK, Kyocera, Samsung, Intel, and LG also began researching FBAR technology, but the following four core structures have been successfully mass-produced in the consumer electronics field: Broadcom's Swimming Pool with Air Frame, Taiyo Yuden's Pop-Up bubble-style cavity, Akoustis's XBAW single-crystal piezoelectric structure, and Newsonic's D-BAW® (double-sided bonded bulk acoustic wave) structure.

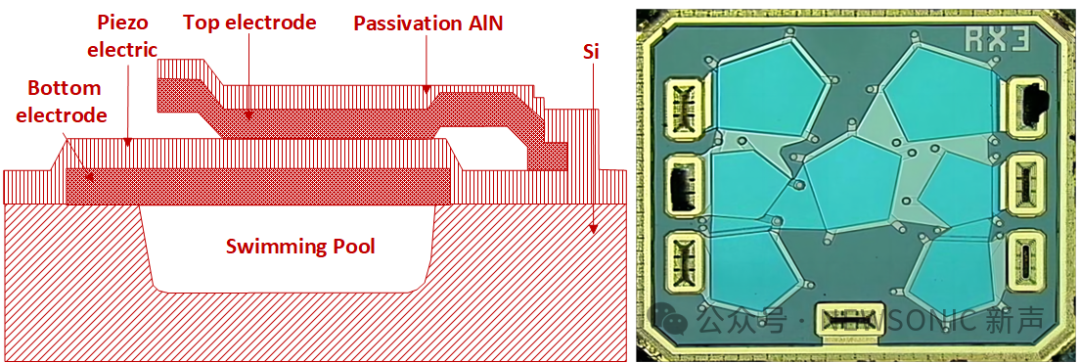

This structure etches a cavity (Swimming Pool) in the silicon substrate to ensure that the core vibration area of the resonator is suspended, with air on both sides of the resonator film. Since the acoustic impedance of air is much lower than that of the piezoelectric layer, most of the acoustic waves are reflected back, effectively improving the resonance efficiency and frequency selectivity of the acoustic waves, making the filter perform better when processing high-speed and high-frequency signals. The Air Frame design further reduces the overall acoustic loss, with a structure similar to an overhanging eave, greatly reducing the lateral leakage of energy and improving the Q value of the resonator, ensuring the purity of signal transmission.

Figure 6. Broadcom FBAR structure schematic

After the mass production of Broadcom's FBAR structure in 2001, it was unrivaled in the field of mobile communication until 2006 when Taiyo Yuden released its own FBAR structure and successfully applied for a patent, and the FBAR market began to be dominated by two giants.

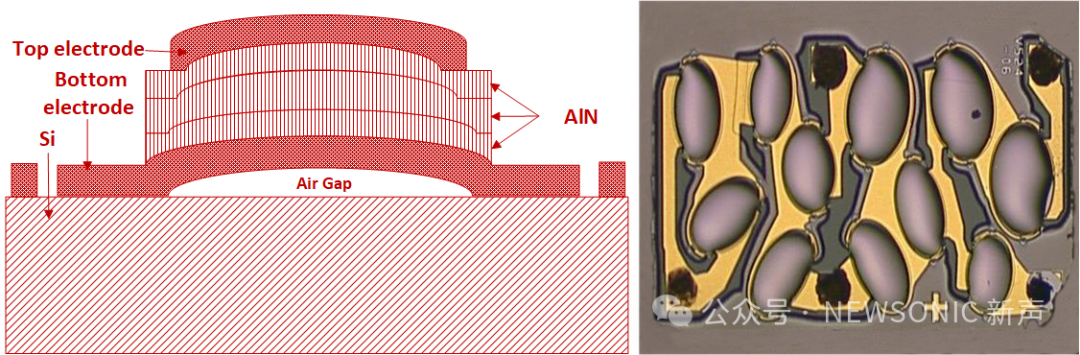

Different from Broadcom's lower cavity structure located in the silicon substrate, Taiyo Yuden's FBAR structure has a lower cavity on the top of the substrate. Before making the piezoelectric layer, a sacrificial support layer is deposited, and then the support layer is removed, forming a bubble-like air cavity similar to a bubble under the resonant cavity. Its principle is the same as Broadcom's air cavity structure, both using the lower acoustic impedance of air compared to the piezoelectric layer to concentrate the acoustic waves for propagation inside the resonator, enhancing the resonance efficiency.

Figure 7. Taiyo Yuden FBAR structure schematic

Akoustis: XBAW single-crystal piezoelectric structure

In 2016, Jeffrey B. Shealy and Michael Hodge and others prepared an FBAR structure with a single-crystal AlN piezoelectric thin film epitaxially grown on a silicon carbide (SiC) substrate, that is, XBAW. Compared with the FBAR filters made of traditional polycrystalline AlN materials, XBAW has a higher inherent crystal quality. XRD test data show that its FWHM value is less than 0.1, far lower than the 1.4 of polycrystalline AlN, so it can obtain higher sound speed, lower material damping loss, and higher electromechanical coupling coefficient, and theoretically, the performance can be greatly improved.

Figure 8. Akoustis FBAR structure schematic

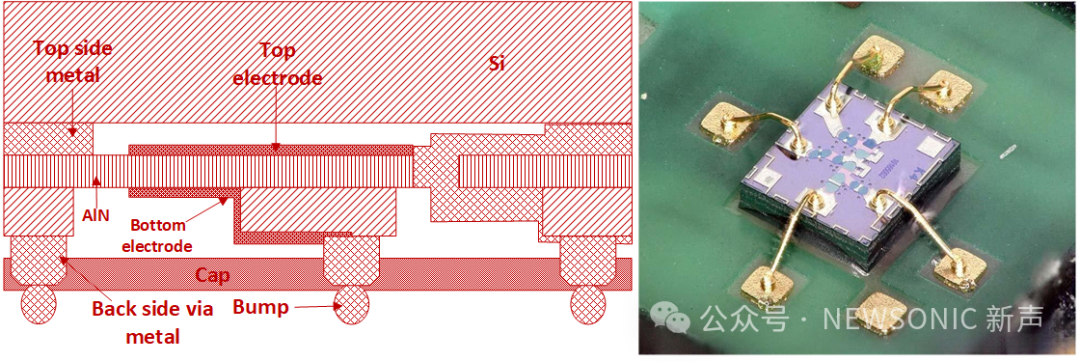

In 2021, Newsonic proposed a brand-new FBAR structure, D-BAW (Double Side Processed Bulk Acoustic Wave Technology), using double-sided bonding to form a cavity structure and achieving double-sided lithography, with the top electrode lithographed on the front and the bottom electrode lithographed from the back, which is significantly different from the three aforementioned FBAR structures. This new structure and process path is achieved on the shoulders of the development of double-sided lithography alignment, precise grinding, bonding technology, and wafer-level packaging in MEMS wafer processing over the past ten years.

Figure 9. Newsonic’s D-BAW structure schematic

As a new member of the FBAR family, D-BAW has the following features:

1) Double-sided lithography and precision processing allow for more flexible and accurate fabrication of various Frame structures on the edges of the upper and lower electrodes, making the D-BAW resonator more efficient in suppressing the propagation of lateral acoustic waves;

2)Double-sided bonding forms a cavity, and the two bondings complete the transfer of the core resonator structure while achieving the suspension of the structure;

3) Fewer photomask layers are required, as the double-sided processing technique simplifies the structure, There is no need to add complex compensatory structures such as Air Bridge to eliminate various acoustic and electrical parasitics, significantly reducing the number of photomask layers and costs;

4) It breaks through material limitations, permitting the use of various substrate wafers, including silicon carbide, glass, gallium arsenide, etc., and various piezoelectric materials such as single-crystal piezoelectric materials, as well as thin-film lithium niobate and tantalate, all of which become viable candidate materials;

5) The AlN piezoelectric layer is extremely flat, with better sputtering coating quality, eliminating boundary losses caused by step undulations in the structure, approaching the ideal piezoelectric capacitor, and offering better performance;

6) Higher electromechanical conversion efficiency is achieved as the photolithography of the upper and lower electrodes on both sides does not need to consider the mutual influence of traditional single-sided MEMS bottom-up processing, allowing for a complete correspondence to the resonant cavity, reducing parasitics, and enhancing the electromechanical conversion efficiency.

The development of technology often relies not on the invention of a single idea, but on a long-term process of accumulation and innovation, and the evolution of FBAR technology is no exception.

*Images without a specified source are from publicly available online materials.

References

[1] Thin Film Bulk Wave Acoustic Resonators (FBAR) for Wireless Applications. (Richard C Ruby)

[2] Acoustic bulk wave composite resonators.( K. M. Lakin and J. S. Wang)

[3] MiCROMACHINED CELLULAR FILTERS ((Richard Ruby)

[4] AN AIR-GAP TYPE PIEZOELECTRIC COMPOSITE THIN FILM RESONATOR(Hiroaki Satoh, Yasuo Ebata)

[5]《RF Bulk Acoustic Wave Filters for Communications》(Ken-ya Hashimoto)

[6] Research and simulation of FBAR oscillation technology. (Wang Qing)

[7] 5G high frequency band highlights the advantages of FBAR filter, and domestic high-end filter challenges and opportunities coexist under the monopoly pattern

[8] Research progress of High performance acoustic filter technology [2021]